Digital Transformation

Digital Transformation Empowers Steel Company

Streamline Operations and Enhance Customer Satisfaction

A Steel Sheets Producing and Selling company sought assistance in transforming their traditional business processes. They faced challenges due to the complexity of their workflows and the lack of suitable infrastructure options.

The solutions available for large businesses proved to be too costly, while those designed for small businesses lacked the necessary capabilities.

Matican Group LLC conducted field research and defined processes that matched the company’s employees’ education level and habits. The company used the same processes they were doing traditionally and converted it to a digital solution with the least habit break possible.

Client Challenges

Steel companies that do business traditionally may face several problems that can negatively impact their operations and bottom line. Here are some examples of problems that steel companies may encounter when doing business traditionally:

Difficulty in Tracking Inventory and Stock Levels

Steel companies may have a hard time keeping track of the raw materials they have on hand and the finished products they have available for sale. This can lead to stockouts and lost sales, as well as wasted raw materials and excess inventory.

Lack of Transparency and Visibility

Traditional business practices may make it difficult for steel companies to keep track of orders, payments, and other key business metrics. This can lead to delays in fulfilling orders, lost sales, and difficulty in managing cash flow.

Difficulty in Scaling Operations

Traditional business practices may make it difficult for steel companies to keep pace with market changes and adapt to new business opportunities. This can lead to lost sales and difficulty in growing the business.

Human Errors

Traditional manual processes can lead to human errors, for example wrong invoicing, wrong pricing, shipping to wrong address, which can lead to financial losses, customer dissatisfaction, and legal issues.

Manual and Time-Consuming Sales Processes

Traditional sales processes may involve a lot of manual paperwork and require a significant amount of time to complete. This can lead to delays in processing orders, poor customer service, and lost sales.

Lack of Communication and Coordination Among Employees

Traditional business practices may make it difficult for employees to share information and collaborate effectively. This can lead to delays in fulfilling orders, poor customer service, and lost sales.

Lack of Employee Performance Evaluation

Traditional business practices may make it difficult for steel companies to evaluate employee performance, leading to lack of motivation, lack of employee retention, and difficulty in identifying top performers.

Lack of a Blacklist

Traditional business practices may make it difficult for steel companies to keep track of customers who have a history of non-payment or other issues. This can lead to financial losses and difficulty in managing cash flow.

The Solution

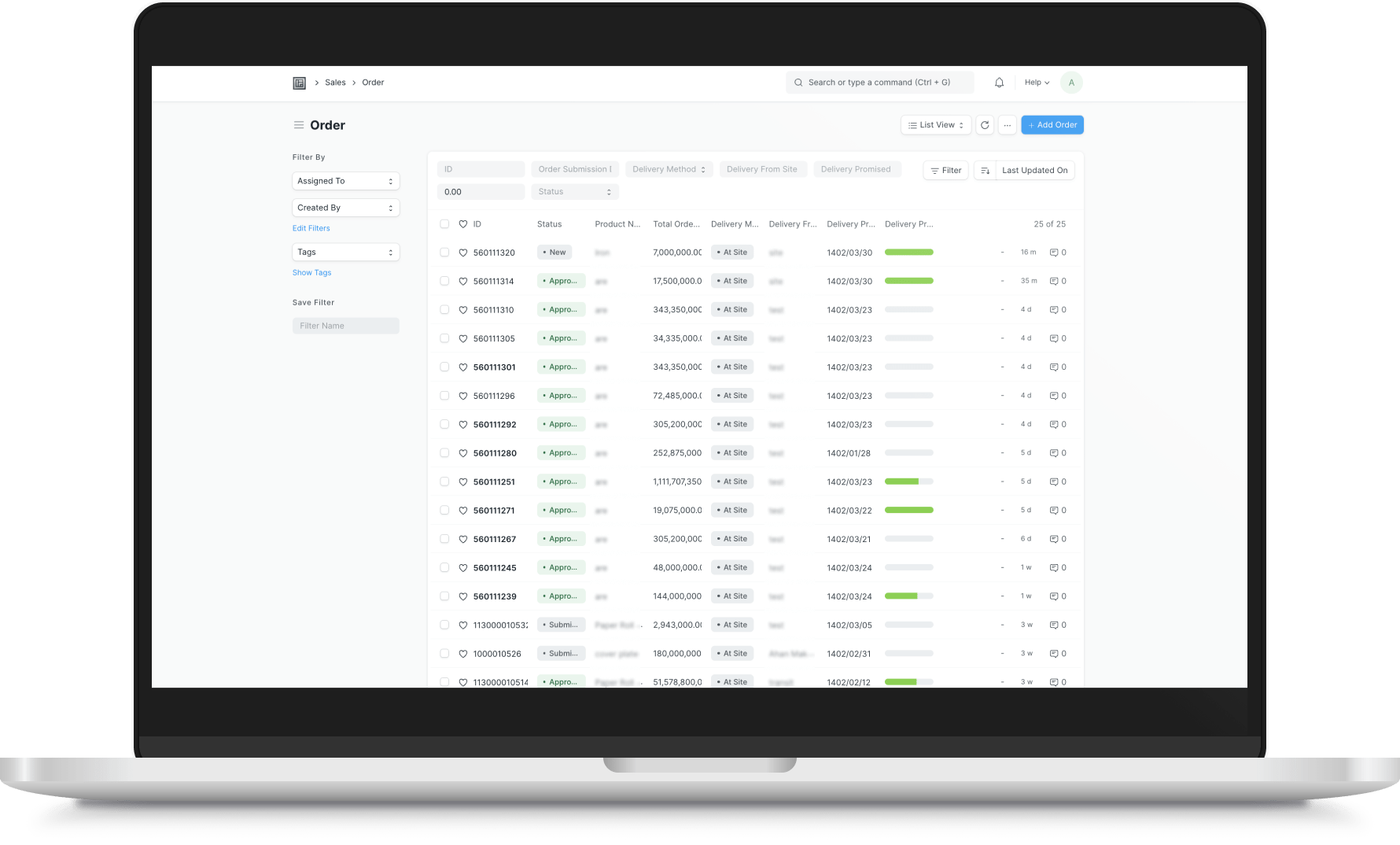

The solution developed by Matican Group LLC for the Steel Sheets Producing and Selling company provided several features to improve organizational efficiency, reduce the risk of errors and financial losses, and increase customer satisfaction. Here are some of the key features in more detail:

Dynamic Payment Conditions

The solution was designed to handle different payment terms for different customers, allowing for flexibility in financial arrangements. This feature enables the company to offer custom payment terms to different customers based on their creditworthiness, history, and volume of business.

Inventory and Stock Management

The solution included features for tracking inventory and managing stock levels, taking into account the weight loss that occurs during the melting process. This feature helps to ensure that the company always has enough raw materials on hand to fulfill customer orders while minimizing waste and excess inventory.

Classification of Information

The solution included tools for organizing and managing information, allowing for easy sharing of data between salespeople. This feature enables the sales team to access customer information, order history, and sales reports, which helps them to better serve their clients and increase sales.

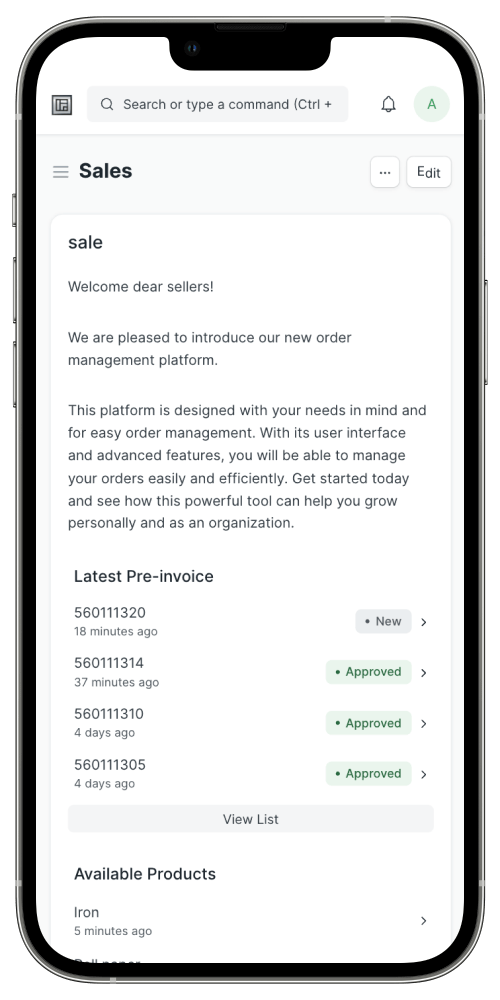

Streamlined Sales Processes

The solution was designed to speed up sales processes, reducing time spent on administrative tasks and improving customer satisfaction. This feature enables the sales team to focus on selling and servicing customers, rather than on administrative tasks.

Payment Follow-up

The solution included tools for tracking and managing customer payments, making it easy to follow up on overdue payments. This feature enables the company to better manage its cash flow and reduce the risk of bad debt.

Live Overview

The solution provided real-time visibility into the company’s operations, allowing stakeholders to stay informed about the latest developments. This feature enables managers to make better-informed decisions and respond quickly to changes in the market.

Price Accuracy

The solution was designed to minimize human error and ensure that products were sold at the correct price. This feature reduces the risk of financial losses due to pricing errors.

Blacklist

The solution included a feature for creating a blacklist of customers who had a history of non-payment or other issues. This feature helps to protect the company from financial losses due to bad debt.

Employee Rating, Raises and Promotions

The solution included tools for evaluating employee performance and managing career development, helping to ensure that top performers were rewarded and retained. This feature enables the company to improve employee performance and retain top talent.

Lack of Efficiency

The solution was designed to streamline processes and reduce downtime, increasing overall efficiency and productivity. This feature enables the company to improve its bottom line by reducing costs and increasing output.

Selling a Product that Was Not Available in Inventory

The solution included inventory management features that alerted salespeople when a product was not available in stock, reducing the risk of overselling and disappointing customers.

Order Tracking for Customers

The solution also provided customers with the ability to track their orders in real-time through an online portal, using a unique order tracking code sent via SMS. This improved transparency and accountability and helped to increase customer satisfaction by providing them with real-time information about the status of their orders.

Separation of Clientele Between Sales People

The solution implemented controls that restricted access to client information among salespeople, fostering a healthy competition among its sales team while ensuring that sales processes were carried out in a professional and ethical manner.

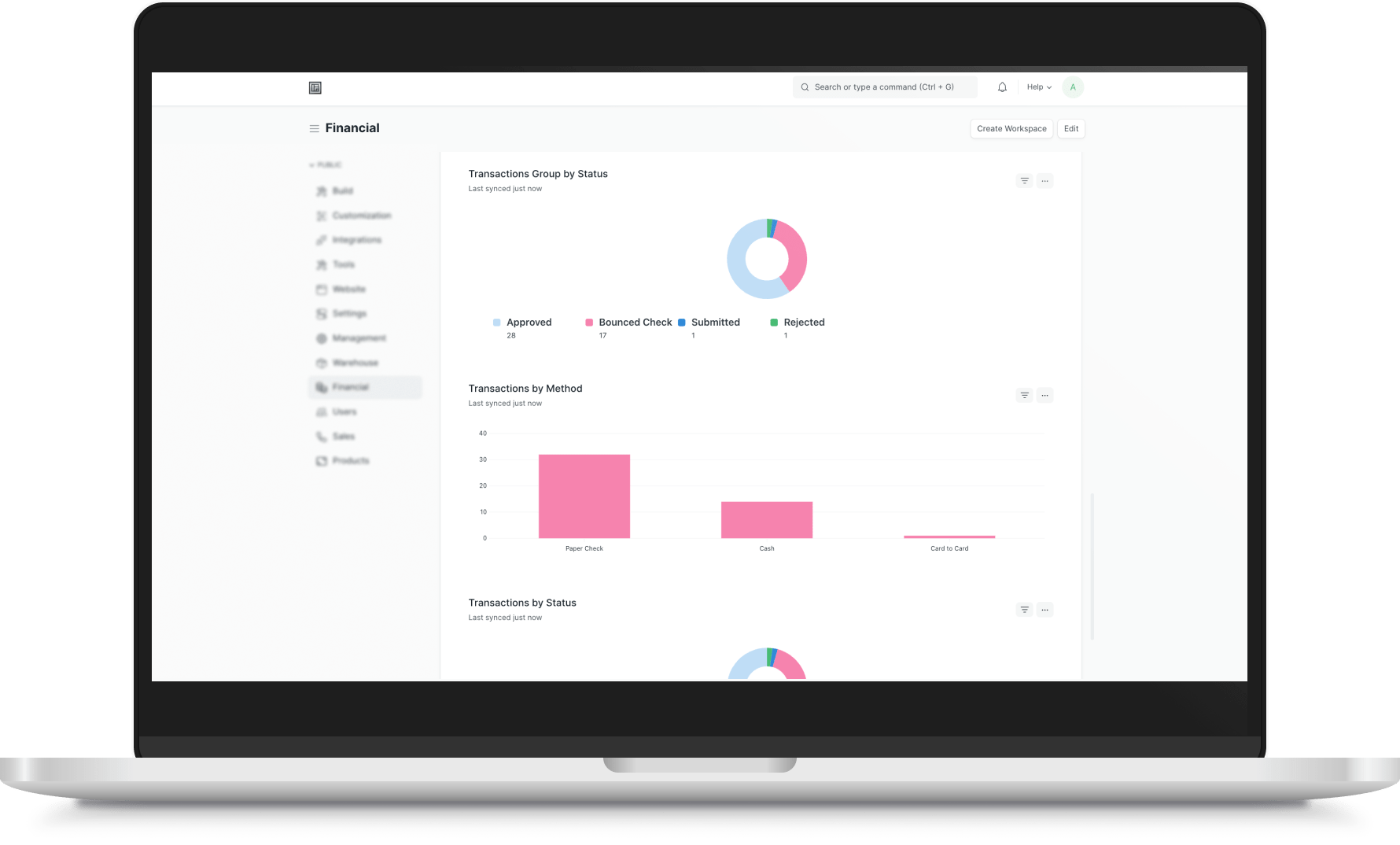

Intuitive Dashboard for Steel Company Managers

The live workflow processes enabled steel company managers to monitor the progress of each order delivery in an intuitive dashboard. This provided them with a real-time view of the entire sales pipeline, from the moment an order was placed to the moment it was delivered.

SMS and PUSH Notification for Specific Order Approvals

The solution also provided a feature for the sales manager to receive SMS and push notifications for orders over a certain value, providing an additional level of oversight and control over the sales process. This ensured that high-value orders were handled with extra care and attention.

Maintenance Schedule of Their Production Line

The solution included a maintenance schedule feature that helped to ensure that the production line was kept in good working order, reducing the risk of downtime and prolonging the lifespan of equipment.

Customizable Print Templates

The solution also provided the ability to define or customize print templates, making it easy for steel company managers to adapt to what their customers understand better. This feature helped the company to adapt to the specific needs of its customers, ensuring that they received the information they needed in a format they could understand.

Kanban Boards to Follow up Orders and Live Notifications Between Employees

The solution enabled the Steel Sheets Producing and Selling company to use Kanban boards to track orders and monitor progress in real-time. This helped to improve visibility into the sales pipeline and ensure that orders were fulfilled on time.

Managing Suppliers and Keeping Track of Their Raw Material Providers

The solution included tools for managing supplier relationships and tracking deliveries of raw materials, helping to ensure that the company had the resources it needed to keep production running smoothly.

With this solution, the company was able to improve organizational efficiency, reduce the risk of errors and financial losses, and increase customer satisfaction. The solution also helped the company to scale its operations and keep pace with market changes.

The solution also provided the ability for customers to submit orders and receive a detailed printed order with all the details needed and also truck drivers receive their payments on time and also salespeople’s commissions are calculated automatically that prevents fraud.

The ability to define or customize print templates made it easy for steel company managers to adapt to what their customers understand better.

Customers when submitting their orders receive the order tracking code through SMS and they can follow up their order and its delivery through an online portal.

And also due to live workflows processes, Steel company managers are capable of seeing progress of each order delivery in an intuitive dashboard.

The Steel Sheets Producing and Selling company was able to benefit from a tailor-made solution that perfectly matched its specific needs, resulting in improved efficiency and heightened customer satisfaction. This allowed the company to effectively scale its operations and stay adaptable to market changes.